Methods of Marking

We're the first name in hallmarking.

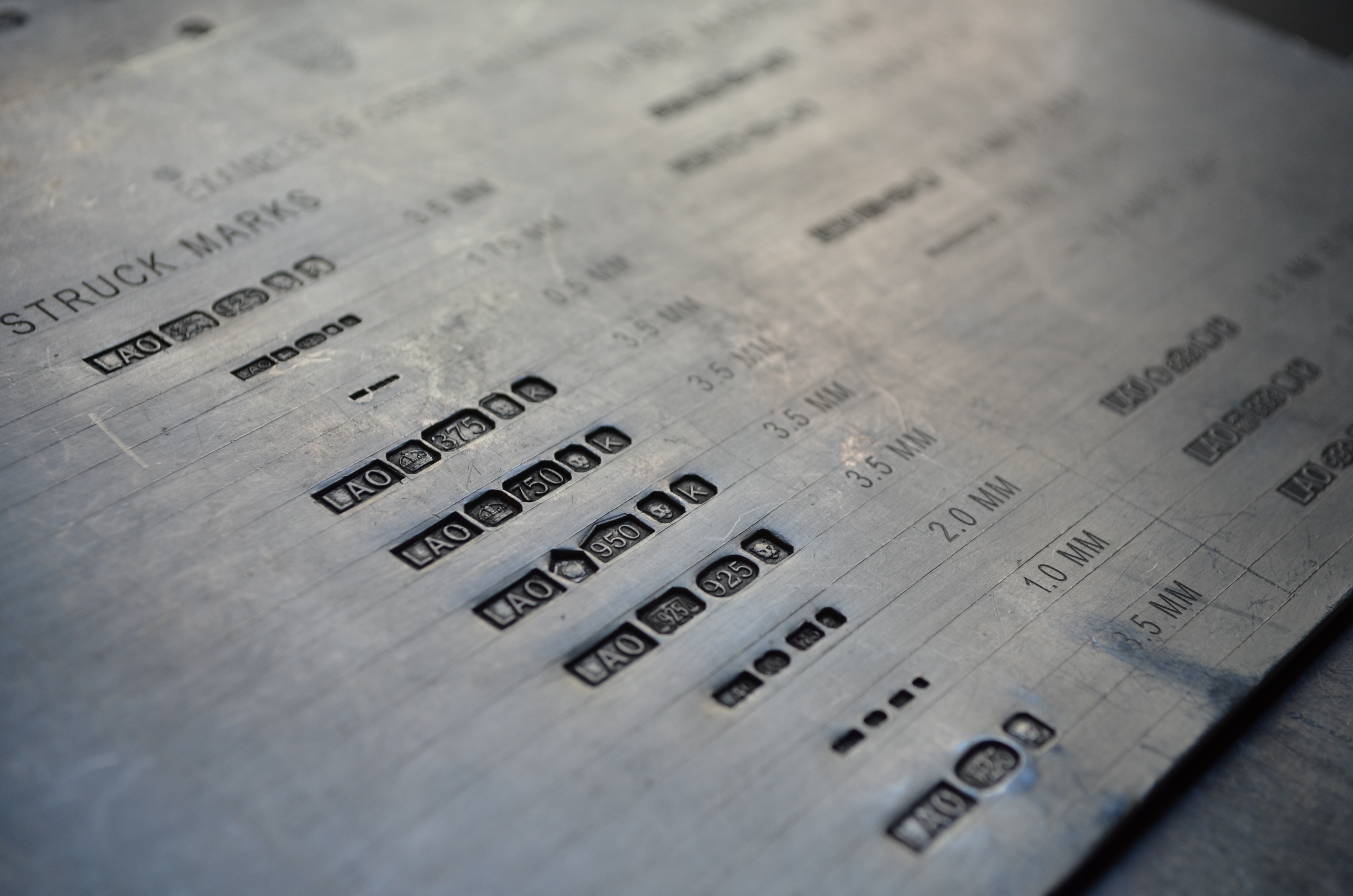

Struck Marks

Traditional struck marks are made with a punch, creating an impression by moving (forming) the metal - this can leave a slight 'bruise' on the metal, or can distort it (depending on the thickness). This can be removed by an experienced jeweller or silversmith by filing and finishing, a process known as 'setting back'. (See video below)

If your work is unfinished, a struck mark is recommended as the result is deep, and can then withstand plating and general finishing. This hallmark will last a lifetime.

Handmarking is the most traditional method of hallmarking, and is carried out using a punch and hammer. This type of marking is not recommended for very thin metal, delicate or hollow articles.

Pressmarking is another traditional form of hallmarking. Essentially it is an automated version of handmarking with marks applied using fly press or air press. The process is often used for large runs of the same or similar type of article.

Punches

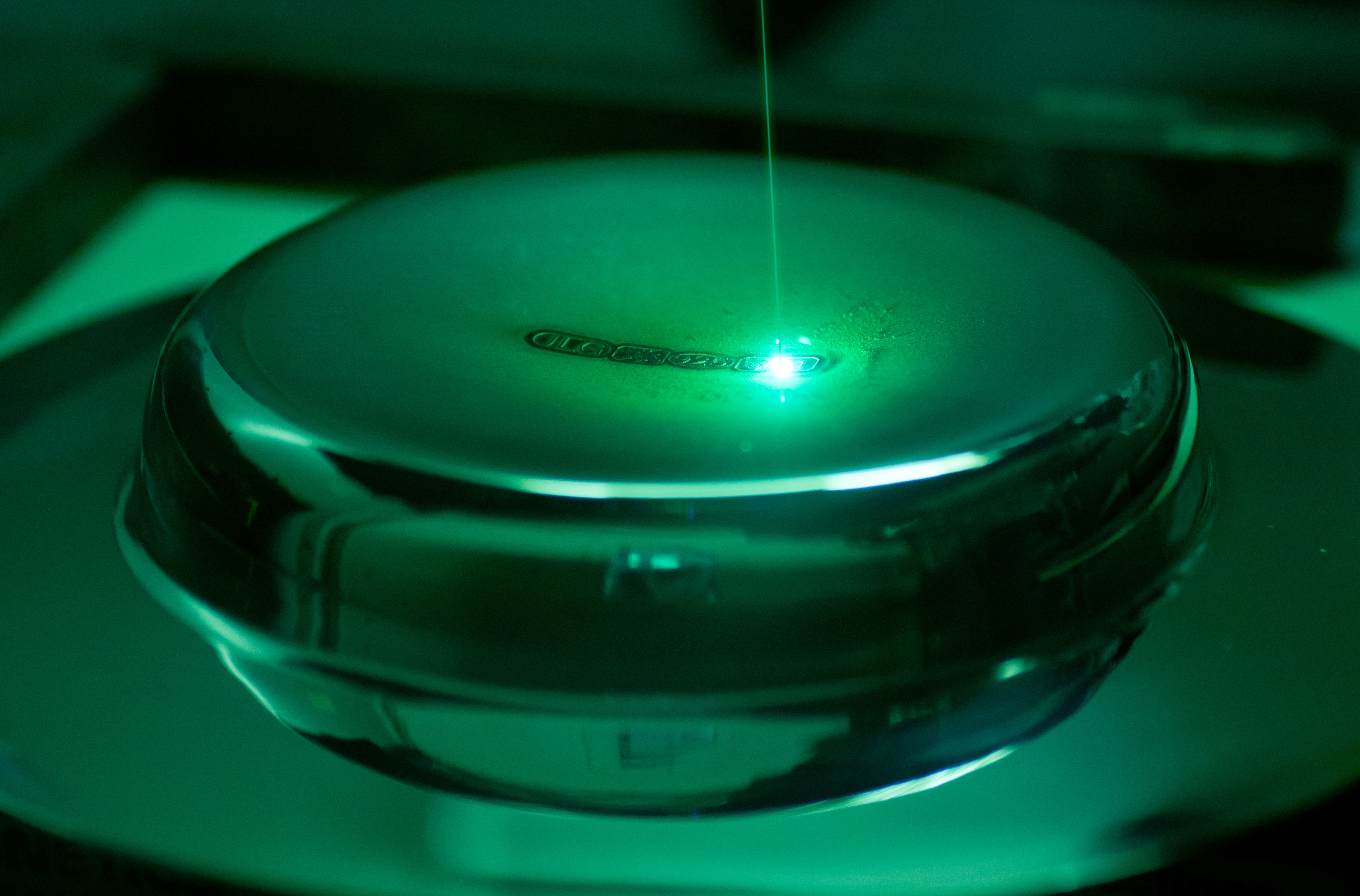

Laser Hallmarking

If your work is finished and polished, a laser hallmark is ideal as the process does not displace the metal so you won't need to set it back.

Laser Marks are made with either a fibre, lamp pump, or diode laser - all three are used across our offices. A very fine, high powered beam vapourises the surface of the metal and etches on the hallmarks.

Laser marking is the most recent method of applying the hallmark.

The limited depth of focus on a laser makes flat articles, such as watch backs, photo frames, tops of cufflinks, and flat areas on large wares the best suited to laser hallmarking.

Marking on curved articles is possible when the radius of curvature is sufficiently shallow to maintain focus (a smaller size/length mark often helps for those articles).

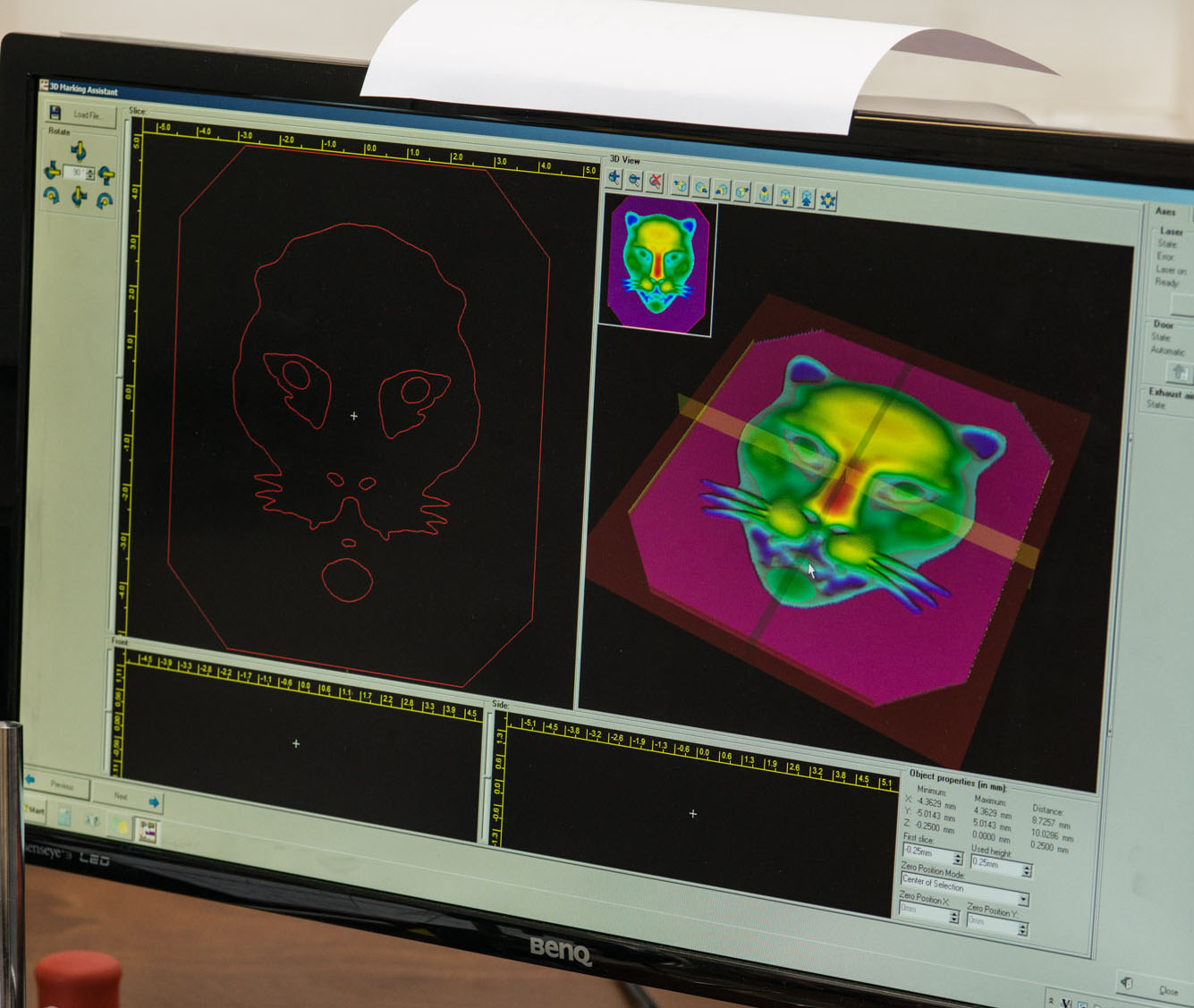

We currently offer two different types of laser hallmark:

- 3D laser mark: Creates a deeper, more detailed result. Would withstand a very slight polishing.

- 2D laser mark: Resembles the outline of a struck mark. Creates a simple outline of the hallmark. It is very light so strictly for finished items only.

It is great for marking thin, hollow or more delicate items. Castings and unfinished items are unsuitable as a laser mark can only withstand a light polish.

We also offer laser engraving services.

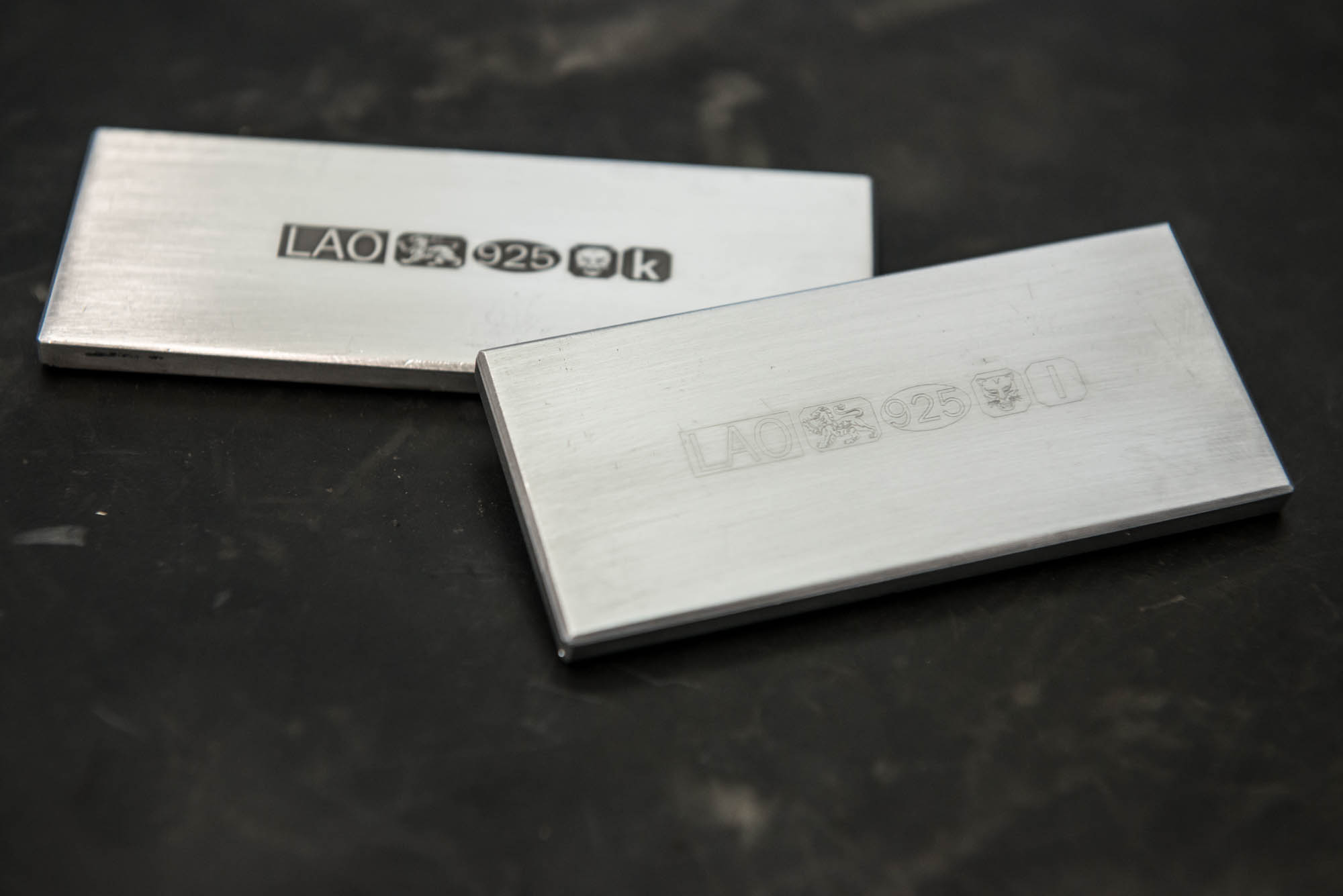

Comparison of laser mark (back sample) and struck mark (front sample)

Comparison of 3D laser (back sample) and 2D laser (front sample) marks

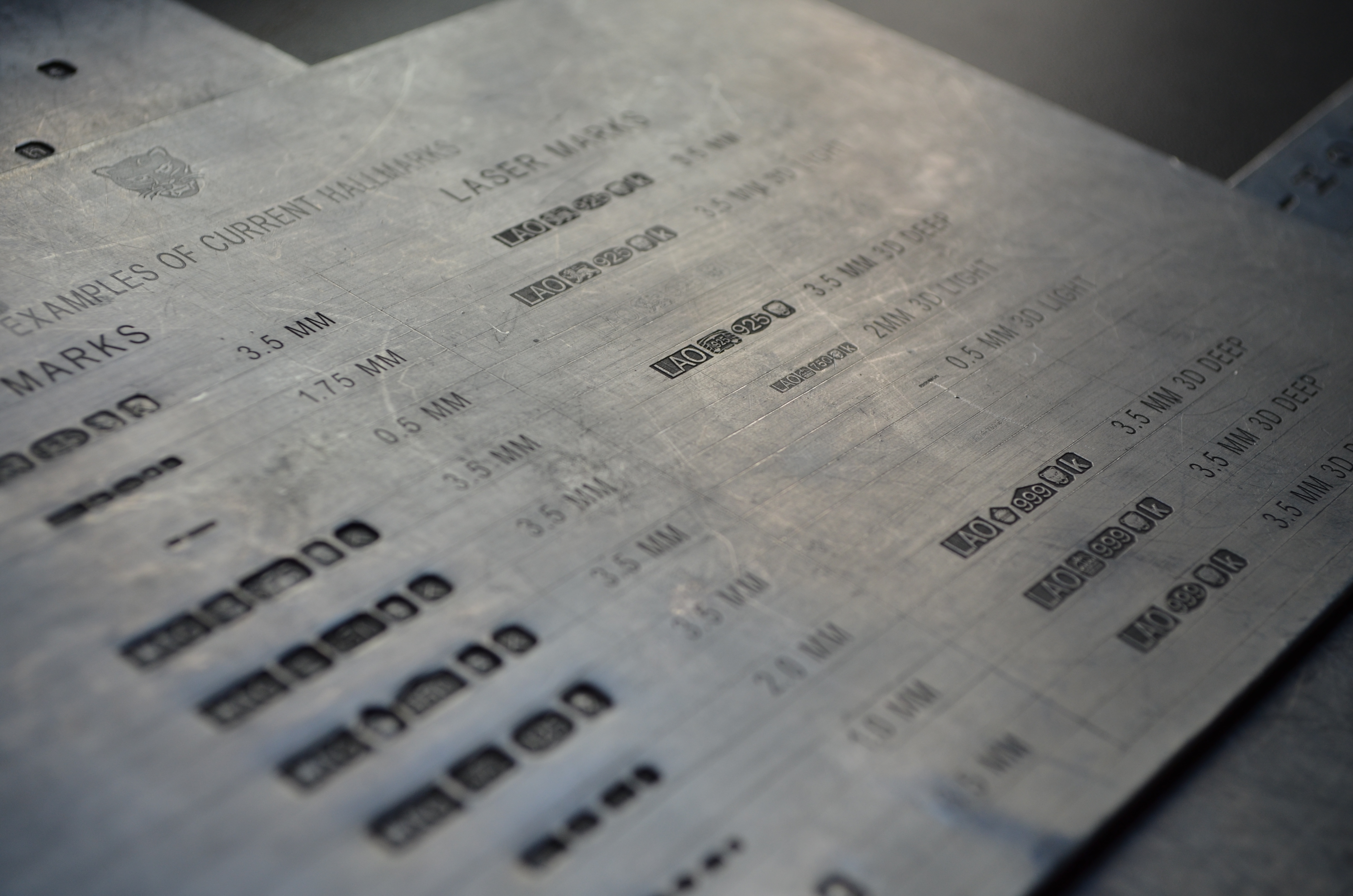

Sheets showing struck marks...

...and laser marks

Size Guide

| Size | Height | Use |

|---|---|---|

| A | 6.00mm | Large Silver Holloware |

| B | 5.00mm | Large Silver Holloware |

| C | 4.25mm | Large Silver Holloware |

| D | 3.50mm | Small Silver Holloware |

| E | 3.00mm | Small Silver Holloware |

| F | 2.50mm | Small Silver Holloware |

| G | 2.00mm | Small Silver Holloware |

| H | 1.75mm | Napkin Rings, Frames |

| I | 1.50mm | Napkin Rings, Frames |

| J | 1.25mm | Napkin Rings, Frames |

| K | 1.00mm | Solid Bangles, Large Jewellery |

| L | 0.75mm | Rings |

| M | 0.50mm | Small Jewellery, Rings |

Struck hallmarks are available in sizes 0.5mm to 6mm (height). It is worth noting that when struck by a punch, the hallmark will appear very slightly larger.

Laser marks are also available in the same sizes, however due to the difference in application, laser marks can be applied to items at a larger size than the recommended struck marks.

The size of the punch should reflect the type of articles to be hallmarked, and choosing the correct size is paramount. A large punch will be unsuitable for delicate items as the punching process will displace the metal.

If choosing a large punch it is very likely to cause distortion. When submitting smaller jewellery items, including earrings, jump rings on chains or small pendants, we recommend choosing a size M (0.5mm) or size L (0.75mm) punch.

Top: Swan Neck Punch, Bottom: Straight Punch

Development of Marking Technology

The image shows struck hallmark at top, and laser marks beneath.

Download an article from the Goldsmiths' Technical Journal to read more about the development of both methods.

ON YOUR MARKS; THE DEVELOPMENT IN ASSAY OFFICE MARKING TECHNOLOGYYou Tube video of how to we hallmark a silver tray, made at Goldmiths' Hall in 2011.

Scroll through carousel of images below to see each method of marking.